How to Construct a Shed

Prefer this guide as a PDF?

Before You Start

- Do you need permission to erect a structure of this size?

- Check for utilities and any drainage problems

- If the structure is near property ensure rain runoff slopes away from the property

- Clear the base area of grass, rubble, etc.

- Mark out the base of construction with pegs and string, this will give a feel of the overall dimensions

- Check that the height of the finished building does not obstruct your or neighbours view.

- Assemble all tools required as given in assembly instructions. Basic items required will be: spirit level, tape measure, string, plumb line, screwdrivers, hammer, shuv holer for posts

- Layout all the pieces of the project, ensuring all items required are easily identified, also all fittings are correct

- Wear suitable protective clothes, sturdy work boots, gloves and goggles if appropriate

Standard Shed Fixing Kit

- 50 x 8 x 2½ screws (60mm)

- 100 grams x 40mm Galvanised Nails

- 200 grams x 13mm Galvanised Felt (clout) nails

- 18 x 25mm (1”) Galvanised Nails (tacks for window beading)

- 3 x 200mm (8”) light Tee Hinges

- 1 x Door Bolt

- 2 x Galvanised Turn Buttons

- 27 x 8 x 1” screws (for hinges, bolt and turn buttons)

- 4 x M6 x 60 CSH bolts, nuts & washers. (for door bolt)

- 1 x Instruction sheet

- 1 x Silicone sealant (for windows)

For Double Door Shed:

Same as Standard Shed Fixing Kit, plus...

- 27 x 8 x 1” screws

- 1 x Door Bolt

- 4 x M6 x 60 CSH bolts, nut and washer

Step 1

Prepare a base according to 'Constructing a Suitable Base'.

Step 2

Put the floor on the prepared base. The floors are treated and have battens running along the floor about 350mm apart. (Particularly with Pent sheds - Do not confuse the floor with the roof which is larger than the shed base). If your shed is a larger design, there may be more than a one-floor section. If this is the case, ensure that they are butted together as tight as possible and that you put the 2 straightest edges together.

Step 3

Take one end panel and one side panel and stand them on the floor with the lip on the panels overhanging the floors. Ensure that the panels are level with each other and screw these together. Place the remaining panels one at a time alongside and screw together. When all the side panels are screwed together, walk round the shed and ensure that they are sitting squarely and evenly on the floor. When you have done this, screw through the battens on the bottom of the side sections into the floor. - Use 60mm screws on the apex end or pent end sections and screw into the floor battens.- Use 60mm screws on the sides.

Step 4

Fitting the roof. On Apex sheds 2.4m wide and over you will normally be supplied with a Ply or 100mm x 50mm or 75mm x 50mm roof truss. Fit this in place. (There will normally be a timber support fitted into the apex end for this to sit on). - Secure in place with 60mm screw from the outside, being careful not to split the end wood. The notches in the roof (between the cross beam and edge) are to allow the roof to sit over the end sections.

Step 5

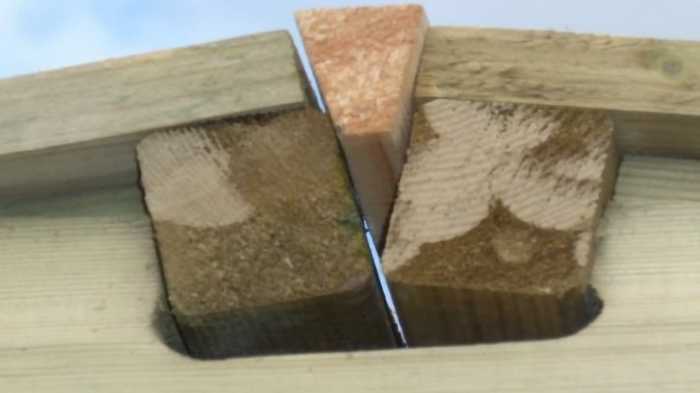

On large roofs where each side is provided in 2 sections, fit the first roof into place ensuring that it is exactly halfway on the shed and just tack into place. Put the other roof up into place and ensure that it is in line with the first roof. When you have done this, screw through the centre battens of the roofs to join them together. As you have to screw through at an angle it can be awkward. The secret is to screw through as low as possible. If you cannot get the roofs to be square with each other then the problem is with the base. What you need to do is to lift one of the corners of the shed and you will see the roof either square itself up or get worse. When you have lifted the roof enough put some packing underneath that corner. You then have to screw the roof onto the shed. This is done by screwing through the roof into the side panels, about every 600mm using a 60mm screw. Try to make sure that the screws go through into the vertical battens of the side walls.

Step 6

You then have to felt the shed. Cut the felt to length. It needs to be 125mm longer than the roof. On 1.2 and 1.5 apex & pent sheds you will need 2 lengths. On 1.8 to 2.4 apex & pent sheds, you will need 3 lengths. On sheds 2.7 and 3.1 apex & pent you will need 4 lengths. Lay the felt on the shed horizontally, starting at both lower sides on an apex shed or just at the lower edge on a pent shed. Use 3 roofing tacks to hold this felt in position and then lay the next layer over the top. The last piece of felt on an apex shed will go over the ridge and on the pent shed will be placed at the highest point of the shed. Secure in place using roofing tacks about every 150mm. Ensure that you nail these tacks in squarely and that you nail into the timber and do not nail through the small gaps in the roof. If you do miss the boards, remove the tack and cover the hole with mastic to ensure a watertight finish. Bend the felt over the edges at right angles, cutting the felt at the corners to give a neat finish, and secure with roofing tacks.

Step 7

Nail the fascia boards on evenly with 50mm nails. You will have 4 on apex sheds (2 for each end and which will need the angle cutting on them). On the pent sheds you have 3 fascia boards. There is one on the high side of the shed and 1 to go on both ends. Nail the corner strips on. If the sides are in more than one piece you will have additional strips to cover over where the panels join.

Step 8

On Shiplap sheds the door is screwed straight onto the cladding. Ensure that the hinges are square on the door and level with each other screw the hinges on using 25mm screws. Position the door in the opening as high as possible and with equal distance on either side. Screw the hinges on using 25mm screws. Screw the pad bolt into place using 25mm screws.

Step 9

Insert the glass into the opening from the inside of the shed. Nail the beading to secure it in place.

These instructions cover the majority of the buildings which we manufacture and supply. If they do not appear to cover your building then the basic principle is still the same. However, if you have any problems, then call us on 01934 862710 and we will be happy to help.

The information and advice in this article is provided in good faith and is designed to give general information and guidance. Any reliance you place on such information is therefore strictly at your own risk. If in doubt we strongly recommend you seek professional assistance.

If you need further advice with your purchase please ask our experienced staff, we will be happy to help!